Temperature swings of 30°C in a single day demand flat roof materials with exceptional flexibility. With around 120 yearly thaws annually and 333 sunny days a year, flat roof seam integrity in Calgary gets challenged more than anywhere in Canada. Foot traffic like HVAC servicemen doesn’t make it easier on flat roofs either!

We show Calgarians why SBS is the best flat roofing product for our climate, when TPO can or shouldn’t be a choice and why EPDM is the best balance amongst value and cost.

Flat roofing product benchmarks/performance per type

Flat roofing companies might be sending you different products, pricing and performance information. Explore how these perform under Calgary climate:

Type 1: EPDM (Rubber Roofing) – most popular

EPDM membrane performs rather well in the -20°C winters. Much better than TPO(later on that). With intense UV rays, EPDM seam adhesives wear out faster than manufacturer estimates (expect around 20 years realistically without frequent repairs). Ballast rocks which is poured on top of EPDM product shields it from UV exposure and extends longevity beyond 20-30 years. Its well worth the additional cost. Especially when 90-mil EPDM thickness is used.

Often overlooked, an black EPDM roof without ballast, will absorb heat contributing to high cooling costs (often by up to 10-30%!). So that’s another reason to spend on one.

It might be tricky to find leaks with ballast, but finding a leak on a flat roof isn’t always straightforward because the wide surface they cover, i.e. commercial buildings like malls. For more experienced flat roofers it might be more labour intensive to clear the ballast and identify a leak directly on the EPDM membrane surface. And with ballast e.g. gravel, shielding your EPDM, you satisfy by default the wind uplift requirement as per Alberta’s building code.

With that said, we need to caveat that there’s white EPDM membrane which will decrease UV absorption.

Which builds should use EPDM product for flat roofing?

- Low-slope industrial buildings without much foot traffic – risk of punctures to EPDM membrane.

- Budget-priority projects with shorter expected ownership timelines

- Buildings with few roof penetrations – fewer failure points

- Properties where cooling efficiency isn’t a major concern – unless foam insulating board are used.

- Properties with budgeting in mind.

Who should avoid EPDM in Calgary:

- Restaurants (grease issues accelerate degradation)

- Buildings with frequent maintenance requirements e.g. HVAC (puncture risk)

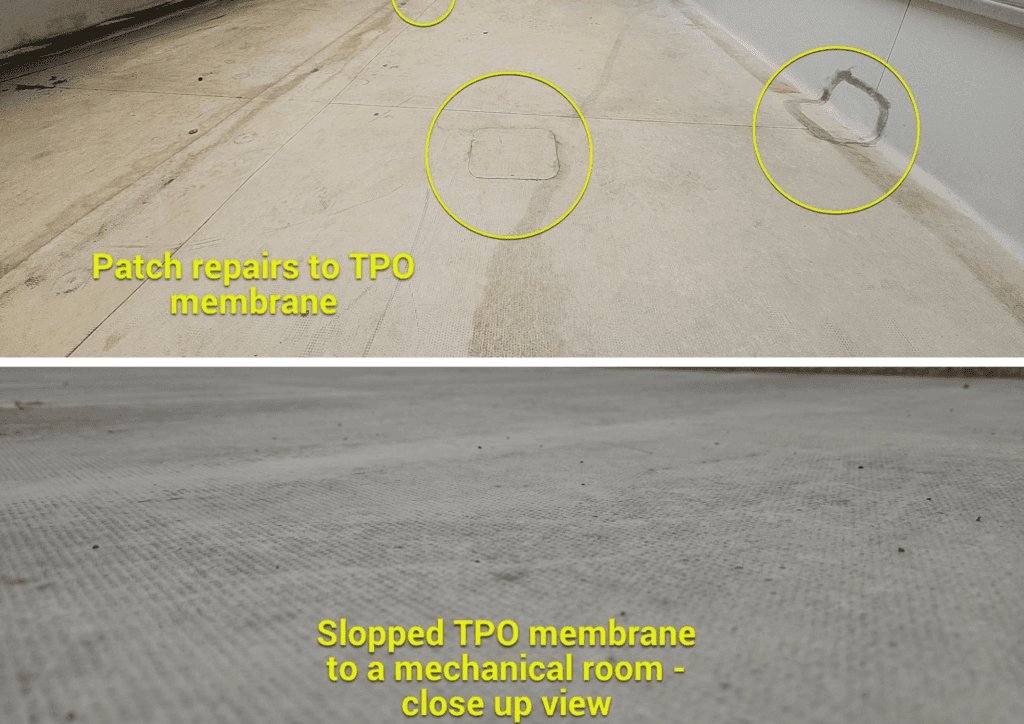

Type 2: TPO (Thermoplastic Olefin) – heat welded

White TPO surface reflects back most of solar radiation. TPO product, reduces heating costs in Calgary. Its heat-welded seams outperform adhesive seams by over 200% in terms of roof repairs needed in the future. Always go with the 60-mil thickness( we recommend Soprema Flagon PZ/SL for its puncture resistance) as it matters with the hailstorms Calgary gets and pay attention to installation temperature as it should be installed above 5°C.

Who should choose TPO in Calgary:

- Commercial buildings with high cooling demands

- Properties with regular HVAC maintenance requiring roof access

- Buildings with multiple roof penetrations where welded seams are crucial

Who should avoid TPO in Calgary:

- DIY installers (requires specialized welding equipment and insurance)

- Projects with tight budgets prioritizing initial cost over relatively said, long-term value – SBS beats TPO (later on that)

- Installations where aesthetics demand colour options beyond white or gray

- If you’re not planning to use ballast

- If you’re a restaurant, as TPO might react to grease

Type 3: PVC (Polyvinyl Chloride)

PVC flat roofing product is superior choice for restaurants with its chemical resistance. PVC maintains it’s flexibility in harsh -20°C winters unlike TPO which stiffens making it more prone to punctures. But that comes with a price as PVC is pricier both as a product and labour expenses.

Who should choose PVC in Calgary:

- Restaurants and food processing facilities (grease exposure)

- Buildings requiring chemical resistance (laboratories, industrial facilities, metal shops)

- Projects where maximum lifespan justifies premium cost

- Areas prone to standing water after Calgary’s rapid snowmelts

Who should avoid PVC in Calgary:

- Environmentally-focused projects (PVC’s manufacturing impact)

- Budget-constrained projects where chemical resistance isn’t necessary

- Buildings where white membrane visibility creates aesthetic concerns

Type 4: Modified Bitumen/SBS (Styrene-Butadiene-Styrene) – the best flat roof material invented by far

- Superior flexibility down to -35°C outperforms all single-ply options in Calgary winters

- Two-ply systems create 3/8″ thickness (375 mil) vs. 60 mil for single-ply options

- Torch-down application creates 300% stronger seams than peel-and-stick in Calgary’s climate

- We rarely recommend the use of peel-and-stick variants for Calgary installations (failure after 10 years)

Who should choose Modified Bitumen in Calgary:

- Buildings requiring maximum puncture resistance (3mm thickness) – Sopralene Flam 180

- Properties with traditional shingle roofs requiring flat sections

- Projects requiring seamless integration with existing bitumen roofing

Who should avoid Modified Bitumen in Calgary:

- Properties with fire concerns (torch-down installation risks) – make sure your contractor has liability insurance

- DIY installers (requires professional installation) – never do it on your own though there’s enough guides online to do so. There’s a high risk of fire.

- Buildings with poor drainage where water might pond – always use the package slope with a professional flat roof installer that knows what they’re doing.

Type 5: Standing seam metal roofing

Standing seam metal roof is a choice for many Calgarians. Unfortunately, price is a setback in 90% of cases for not choosing to go with this type of roof.

- 50+ year lifespan even in Calgary’s extreme conditions (2x longer than membrane options)

- Handles Calgary’s annual freeze-thaw cycles with zero degradation – worry free!

- Insurance premium reductions of 15-25% for hail resistance (with 24 gauge)

- Requires minimum 1:12 pitch for Calgary snow loads (not suitable for completely flat areas)

Who should choose standing seam metal in Calgary:

- Luxury residential properties where aesthetics and longevity trump cost + it’s much more beautiful than corrugated metal plates

- Buildings requiring zero maintenance for decades

- Structures with slight pitch (1:12 minimum) but not completely flat

- Projects seeking insurance premium reductions for hail resistance – discuss that with your insurance carrier to calculate the viability of the project

Who should avoid standing seam metal roof in Calgary:

- Completely flat roof structures

- Budget-sensitive projects (50-75% premium over membrane options)

- Properties where noise concerns exist during Calgary’s hailstorms – especially for dwelling builds

We put EPDM vs. TPO vs. SBS: head-to-head for Calgary

| Feature | EPDM | TPO | SBS Modified Bitumen |

| Winter performance | Good flexibility to -30°C | Becomes rigid below -15°C | Superior flexibility to -40°C |

| UV Resistance | Poor (seams fail first) unless ballasted | Excellent (white surface) – when heat welded | Good (with granular surface) |

| Calgary hail | Poor (punctures easily) | Fair (with 60+ mil) | Excellent (3/8″ thickness) |

| Energy Efficiency | Poor (absorbs heat) – unless using insulation boards | Excellent (reflects UV) | Good (with white granules) |

| Installation season | 8 months in Calgary | 6 months in Calgary | 9 months in Calgary |

| Realistic lifespan | 15-18 years in Calgary | 20-25 years in Calgary | 30-40 years in Calgary |

Calgary flat roof installation environment

Be wary that Calgary’s extreme climate amplifies installation errors. A big percentage of premature flat roof failures trace to installation problems, not material failures. You can check that with a manufacturer like Soprema and their warranty calls.

- EPDM: Use 90-mil minimum thickness (not 60-mil standard)

- TPO: Minimum 60-mil with reinforced seams for hail resistance

- PVC: Double-welded seams for -40°C performance

- Modified Bitumen: ONLY torch-down (NEVER peel-and-stick)

Where does each flat roofing product excels?

Restaurants: PVC exclusively (chemical/grease resistance essential

Warehouses: EPDM for budget concerns & TPO for longevity

Modern Homes: Standing seam metal for aesthetics and longevity

Malls: SBS torch down. Or anywhere else! SBS is the perfect membrane by far as of today for many parameters in Calgary’s commercial roofing branch.

If installation must occur during Calgary winter:

- Modified bitumen torch-down can install at lowest temperatures (even sub-zero) because the torch heats bitumen to melting point regardless of ambient conditions (with proper safety precautions)

- EPDM adhesives typically fail below 5°C (41°F) unless winter-grade adhesives are used, with manufacturer recommendations generally between 5-10°C for proper curing

- TPO/PVC heat-welding becomes problematic below freezing as membranes become rigid and harder to fuse, requiring adjustments like increased weld temperature and slower travel speed to maintain quality.

Eventually, your flat roofing contractor will advise and you should listen

You need a flat roof that will withstand -35°C – 30°C temperatures throughout the year. You need the peace of mind of starting your business or enjoying your dwelling without back and forth with your roofer. It does not go without saying, a reputable flat roofing company in Calgary is not a choice but it will directly impact your building envelope and ultimately your pocket!

That’s why at CPR Group Ltd, we heavily invest in staff training reputable flat roofing suppliers to offer only the best balanced flat roof deliverable to home & business owners in Calgary. It’s crucial for our business to stay ahead of the curve and with the dataset we have for Calgary’s climate, roof longevity and performance we’re able to recommend the right flat roofing products and install them to code.